Produtos / Acessórios para Moldes

Pino Extrator Tipo A DIN 1530

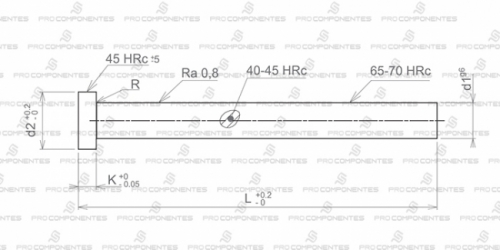

Norma DIN 1530 - ISO 6751

Material Aço H13 (1.2344). Tratamento térmico de nitretação superficial de +/-70 HRC.

Núcleo temperado uniforme por todo o corpo, com dureza de +/-45 HRC.

Cabeças forjadas à quente, garantindo assim resistência.

DisponÃvel também na série PANP (não polido)

Material Aço H13 (1.2344)

Tratamento Térmico de Nitretação

Tabela

| Pino Extrator tipo A - DIN 1530 | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Série PA - PANP | |||||||||||||||

| d1 | d2 | K | R | Comprimento L (mm) | |||||||||||

| 100 | 125 | 160 | 200 | 250 | 315 | 350 | 400 | 500 | 630 | 800 | 1000 | ||||

| 1 | 3 | 2 | 0.2 | 100 | 125 | 160 | 200 | Â | Â | Â | Â | Â | Â | Â | Â |

| 1.5 | 3 | 1.5 | 0.2 | 100 | 125 | 160 | 200 | Â | Â | Â | Â | Â | Â | Â | Â |

| 2 | 4 | 2 | 0.2 | 100 | 125 | 160 | 200 | 250 | 315 | Â | Â | Â | Â | Â | Â |

| 2.1 | 4 | 2 | 0.2 | Â | Â | 160 | Â | Â | 315 | Â | Â | Â | Â | Â | Â |

| 2.2 | 4 | 2 | 0.2 | Â | Â | 160 | Â | Â | 315 | Â | Â | Â | Â | Â | Â |

| 2.5 | 5 | 2 | 0.3 | 100 | 125 | 160 | 200 | 250 | 315 | Â | Â | Â | Â | Â | Â |

| 3 | 6 | 3 | 0.3 | 100 | 125 | 160 | 200 | 250 | 315 | 350 | 400 | 500 | Â | Â | Â |

| 3.1 | 6 | 3 | 0.3 | Â | Â | 160 | Â | Â | 315 | Â | Â | Â | Â | Â | Â |

| 3.2 | 6 | 3 | 0.3 | Â | Â | 160 | Â | Â | 315 | Â | Â | Â | Â | Â | Â |

| 3.5 | 7 | 3 | 0.3 | 100 | 125 | 160 | 200 | 250 | 315 | 350 | 400 | 500 | Â | Â | Â |

| 4 | 8 | 3 | 0.3 | 100 | 125 | 160 | 200 | 250 | 315 | 350 | 400 | 500 | 630 | Â | Â |

| 4.1 | 8 | 3 | 0.3 | Â | Â | 160 | Â | Â | 315 | Â | Â | Â | Â | Â | Â |

| 4.2 | 8 | 3 | 0.3 | Â | Â | 160 | Â | Â | 315 | Â | Â | Â | Â | Â | Â |

| 4.5 | 8 | 3 | 0.3 | 100 | 125 | 160 | 200 | 250 | 315 | 350 | 400 | 500 | Â | Â | Â |

| 5 | 10 | 3 | 0.3 | 100 | 125 | 160 | 200 | 250 | 315 | 350 | 400 | 500 | 630 | 800 | Â |

| 5.1 | 10 | 3 | 0.3 | Â | Â | 160 | Â | Â | 315 | Â | Â | Â | Â | Â | Â |

| 5.2 | 10 | 3 | 0.3 | Â | Â | 160 | Â | Â | 315 | Â | Â | Â | Â | Â | Â |

| 5.5 | 10 | 3 | 0.3 | 100 | 125 | 160 | 200 | 250 | 315 | 350 | 400 | 500 | Â | Â | Â |

| 6 | 12 | 5 | 0.5 | 100 | 125 | 160 | 200 | 250 | 315 | 350 | 400 | 500 | 630 | 800 | Â |

| 6.1 | 12 | 5 | 0.5 | Â | Â | 160 | Â | Â | 315 | Â | Â | Â | Â | Â | Â |

| 6.2 | 12 | 5 | 0.5 | Â | Â | 160 | Â | Â | 315 | Â | Â | Â | Â | Â | Â |

| 6.5 | 12 | 5 | 0.5 | 100 | 125 | 160 | 200 | 250 | 315 | 350 | 400 | Â | Â | Â | Â |

| 7 | 12 | 5 | 0.5 | 100 | 125 | 160 | 200 | 250 | 315 | 350 | 400 | 500 | 630 | Â | Â |

| 8 | 14 | 5 | 0.5 | 100 | 125 | 160 | 200 | 250 | 315 | 350 | 400 | 500 | 630 | 800 | Â |

| 8.2 | 14 | 5 | 0.5 | Â | Â | 160 | Â | Â | 315 | Â | Â | Â | Â | Â | Â |

| 8.5 | 14 | 5 | 0.5 | 100 | 125 | 160 | 200 | 250 | 315 | 350 | 400 | 500 | 630 | Â | Â |

| 9 | 14 | 5 | 0.5 | 100 | 125 | 160 | 200 | 250 | 315 | 350 | 400 | 500 | 630 | Â | Â |

| 10 | 16 | 5 | 0.5 | 100 | 125 | 160 | 200 | 250 | 315 | 350 | 400 | 500 | 630 | 800 | Â |

| 10.2 | 16 | 5 | 0.5 | Â | Â | 160 | Â | Â | 315 | Â | Â | Â | Â | Â | Â |

| 11 | 16 | 5 | 0.5 | Â | Â | 160 | Â | Â | 315 | Â | Â | Â | Â | Â | Â |

| 12 | 18 | 7 | 0.8 | 100 | 125 | 160 | 200 | 250 | 315 | 350 | 400 | 500 | 630 | 800 | Â |

| 13 | 22 | 7 | 0,8 | Â | Â | 160 | Â | Â | 315 | Â | Â | Â | Â | Â | Â |

| 14 | 22 | 7 | 0.8 | 100 | 125 | 160 | 200 | 250 | 315 | 350 | 400 | 500 | 630 | 800 | Â |

| 16 | 22 | 7 | 0.8 | 100 | 125 | 160 | 200 | 250 | 315 | 350 | 400 | 500 | 630 | 800 | 1000 |

| 20 | 26 | 8 | 1 | 100 | 125 | 160 | 200 | 250 | 315 | 350 | 400 | 500 | 630 | 800 | 1000 |

| 25 | 32 | 10 | 1 | Â | Â | 160 | Â | 250 | Â | Â | 400 | 500 | 630 | 800 | 1000 |

Para solicitar o produto especifique:

| Série | d1 | L |

Exemplo: PA 1,5X100

Desenho Técnico